The electrical assistance system includes at least a battery, a motor, a motor controller (sometimes integrated inside the motor), a control and display console. Other elements can be added: pedaling sensor, torque sensor, speed sensor, handlebar accelerator …

2.1. The battery

As explained in Part 1, the batteries supplied with some commercial bicycles cannot be charged during use, which greatly complicates their integration into a solar bicycle.

Battery specifications

The main characteristics of a battery are:

– chemical technology: today, most bicycle batteries use Litium-Ion technology.

– the nominal voltage: 36 Volts, 48 Volts, or even 52 Volts,

– the capacity, expressed in Ampere-hours or in Watts-hours. This value reflects the amount of energy that the battery is able to store and restore.

Components of the battery

A battery is made up of a set of Li-Ion elements (called “cells”) associated in series and in parallel, to which an electronic protection system (BMS) is added. The role of the BMS is to prevent too deep a charge or discharge and to balance the voltages between the Li-Ion cells.

Most batteries are made up of cells called “18650”, with reference to their physical format (diameter = 18mm, length = 65mm).

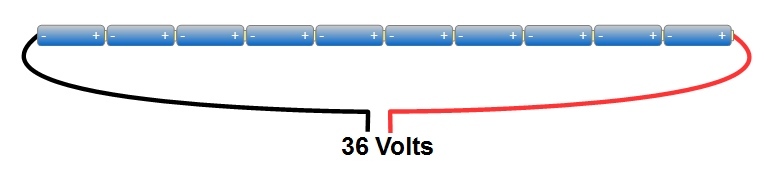

Association of cells in series

The nominal voltage of an 18650 cell is 3.6 Volts.

To make a 36 volt battery, we put 10 cells in series.

For a 48 battery Volts, the series has 13 cells.

For a 48 battery Volts, the series has 13 cells.

Association of cells in parallel

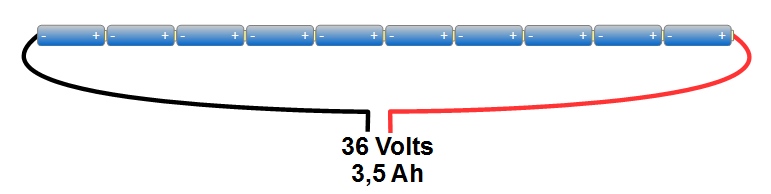

Manufacturers offer 18650 cells in different capacities: 2000, 2500, 2900, up to 3500 Milliampere-hour.

In the example shown below, we have chosen 3500 mAh cells. The set includes only 1 series, its overall capacity is 3500 mAh or 3.5 A-h.

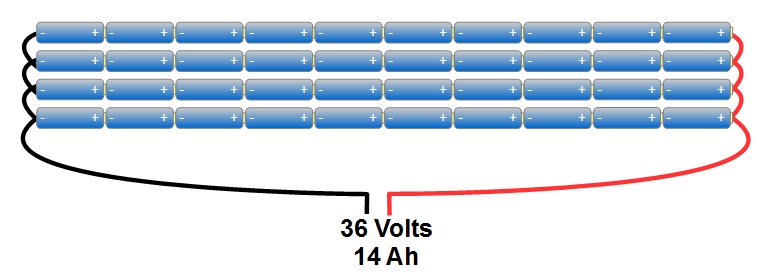

In the second example shown below, still with 3500 mAh cells, 4 series of 10 cells have been associated in parallel. The resulting battery has an overall capacity of 14 A-h.

High capacity cells (3500 mA-h) are often the most expensive, but their advantage is that they can store more energy at equal weight. In other words, at equal capacity, the battery will be lighter, which is an advantage for the solar cyclist.

As for the quality of the cells (capacity, longevity), it is often better among large manufacturers such as LG, Samsung, Sanyo …

2.2. The engine

There are different types of engines, each with advantages and disadvantages. Knowing them will be an asset in making the best choice according to the intended use.

2.2.a. The Direct Drive “wheel” motor

It is inserted into a wheel instead of the hub, this Direct Drive type has no gears inside. There are models for front wheel or rear wheel. Front wheel models can optionally be installed on a trailer.

Benefits: very reliable, no maintenance. On descents, the motor can brake and regenerate electricity to recharge the battery.

Disadvantages: heavier than the reduced motor, and less efficient on very steep hills where it gets hot.

2.2.b. The reduced “wheel” motor

It is inserted into a wheel instead of the hub, it has gears inside. There are models for front wheel or rear wheel. Front wheel models can optionally be installed on a trailer.

Benefits: smaller engine, less heavy, often more efficient than Direct Drive on hills. . It does not brake the bike when pedaling without assistance.

Disadvantages: Gears to be regularly maintained and changed after long distance trips. No regeneration on descents.

2.2.c. The “pedal” motor

This motor is inserted in place of the original crankset, it has gears inside.

Benefits: smaller engine, less heavy, very efficient on hills. It does not brake the bike when pedaling without assistance.

Disadvantages: Gears to be regularly maintained and changed after long distance trips. No regeneration on descents.

2.3. The motor controller

Depending on the system, the controller can be independent or integrated into the engine block. It is very often independent in wheel motor systems and often integrated into pedal motors. Its role is to manage the energy supplied to the motor, as a function of several data (level of assistance chosen, speed, energy available in the battery, signal from the torque or pedaling sensor, etc.).

2.4. The control and display console

It gives indications to the user (eg: speed, level of assistance, battery voltage, distance traveled, etc.) and, moreover, it allows him to communicate with the system (at least to choose the level of assistance).

In advanced systems, such as those manufactured by the company Grin Technologie, the Cycle-Analyst console, allows the display and selection of a very large number of parameters: speed, power consumed, assistance levels, etc. additional equipment allows simultaneous display of solar production. It is thus possible to know in real time the amount of energy consumed and produced.

In the photo above, we can see that the consumption by the motor is 353W at this precise moment, while the solar production is 371W.

2.5. The pedaling sensor or the torque sensor

Depending on the system, this sensor may be separate or integrated into the engine block, in which case it is not visible. The most advanced systems have a torque sensor that measures the power given by the cyclist, the others a pedaling sensor that measures the cyclist’s pedaling pace.

2.6. The speed sensor

Depending on the system, this sensor can be separate or integrated into the engine block.

2.7. The handlebar accelerator

It is an optional accessory. It is authorized in France only for starting, for example after a red light. It is often very useful, especially on recumbent bikes, for hill starts.

Views: 102